- HOME

- U.S. BUSINESS DEVELOPMENT TIPS

- Construction

U.S. BUSINESS DEVELOPMENT TIPS

Recommended Communities

Recommended Communities

New River Valley Economic Development Alliance Virginia's New River Valley is centrally located on the East Coast on I-81 and is the home of VA Tech, Radford University, and New River Community College |

|

Winston-Salem is a diverse and progressive community within a region that is rich in a multitude of resources for helping companies succeed. |

Development Authority of Jeffersonville and Twiggs County Twiggs County is the geographical center of Georgia along Interstate-16 between Atlanta and the Georgia ports and offers over 500acres in the new I-16 Industrial park |

Construction Methods

When preparing for new developments in the U.S., after a prospective site is obtained, an industrial construction company must be selected.

Just as environmental regulations and transportation systems vary from one country to the next, there are numerous differences in the construction field as well.

Here we will introduce the major industrial construction methods in the United States.

A steel structure is typically used when constructing a manufacturing plant in the United States. The 2 methods described below are the most widely used methods for plant construction.

Conventional Method

In the Conventional Method, square or cylindrical shape steel is used for columns, and a truss is used for the beams and the main building. As for the roof, hard exterior insulation materials and water proof sheets are applied to a metal deck, so it is extremely well waterproofed and insulated. The exterior walls are generally metal siding (folded steel plates). This method is suitable for heavy duty plants with large hanging loads, roof penetrations, and many openings. Compared to the Pre-Engineered Method, this method is typically slightly more expensive.

In the Conventional Method, using the tilt up method for exterior walls that utilizes concrete panels instead of metal siding is also common. PC (precast concrete) exterior walls can be found in many countries, but in the tilt up method, the concrete walls that will be used as exterior walls are cast in place. In this case, slab on grade is poured first, and the floor surface isused as a form. Painted concrete exterior walls are visuallyappealing, and some industrial parks that have specific appearance policies recommend or specify the use of the tilt up method. The exterior walls serve as the structural walls, so a characteristic of this method is that there are no columns on the outside of the structure.

Pre-Engineered Method

The Pre-Engineered Method uses wide flange beam or taper steel for the columns, thin plate assembled beams, and Z purlin for purlin for the main building. For the roof, interior insulation materials and metal roofs are used. This water proofing method is slightly inferior to the Conventional Method that uses water proof sheets. Normally in the Pre-Engineered Method, columns, walls, and the roof are all provided as one package. If the building is to be simple and close to standard dimensions, the Pre-Engineered Method will generally be more economical.

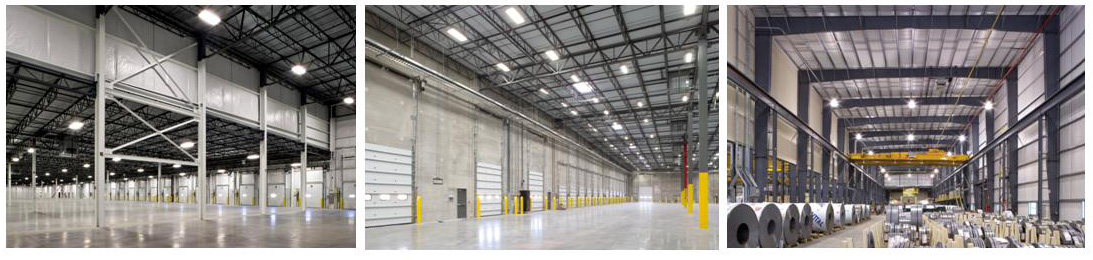

Conventional Method Tilt Up Method Pre-Engineered Method

The construction cost will vary depending on the method you select, so it is extremely important to choose the most suitable construction method for your plant construction needs.

Please inquire to the Snavi Office if you have any questions regarding construction methods, award methods, or plant construction in the United States.